|

DETONATION FLAME ARRESTOR CLEANING & RECONDITIONING |

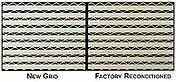

FACTORY EXCHANGE PROGRAM • ARRESTOR GRIDS

|

The Sure Stop Detonation Flame Arrestor Grid assemblies have been extensively engineered and tested to do, not just one job, but many. The Grid assembly is a series of accurately and evenly spaced flat bars that are welded into place in the cell assembly. The grid assembly acts as a container for the flame quenching alumina ceramic media, holding it securely in place. The grid assembly also greatly improves the continuous burn rating, and acts as a protective guard for debris that may travel in the piping system. The assembly is arranged so that it is cleanable and rebuildable, saving future maintenance expenses. TORNADO™ TECHNOLOGIES INC. offers an exchange program that allows the consumer to monitor his Detonation Flame Arrestor, and if the back pressure increases, a replacement cell can be shipped from the factory for exchange. Once the used element has been removed it can then be shipped back to the factory to be cleaned and checked.

|

At the factory the media is removed. Then the cell assembly is sandblasted, cleaning all debris from channels, surfaces and housing. After blasting, a thorough inspection is done to assure that the housing is totally intact. Once the inspection is complete the unit is then recharged with new alumina ceramic, sealed, painted and put in stock.

SERVICES THAT SAVE YOU TIME & MONEY

MEDIA RECYCLING UNIT

|

|

The TORNADO™ Media Recycling Unit is designed to save you money. The rotating drum is built with solid stainless steel construction to eliminate any oxidation during the cleaning process. The steps used in cleaning contaminated beads are very simple. First you dump the dirty beads into the unit along with water and a degreaser cleaning soap. After the beads, soap and water are in place turn on the rotating drum and allow to run 10-15 minutes. Remove the dirty water and rinse. Continue to rinse until the water runs clean. Inspect the beads to ensure that they are clean and free from foreign materials. If they are clean to your satisfaction, use a tiger torch to heat the beads - allowing them to dry. Be careful after heating the beads, they will retain heat - remaining at high temperatures, use caution until cooled.