TORNADO™ TECHNOLOGIES Inc. and TORNADO™ RENTALS have been supplying innovative production equipment to the oil and gas industry for many years. Over the years, we have seen many incidents concerning air being drawn into storage tanks and underground knockout tanks. This condition can be very dangerous and costly due to accelerated corrosion and also may cause internal explosions in the storage tanks. The corrosion problems occur when air is continuously drawn into the tank while fluid is being removed. Also, when air is being drawn into the tank you run the risk of explosions due to the fact that with the new environmental laws most vent lines are tied into a flare header where there is a continuous flame burning. As the air enriched gas stream travels out to the flare stack the air/fuel mixture is stoichiometric and will support a back flash through the piping back to the storage tank.

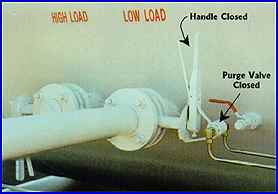

If there is not a TORNADO™

Detonation Arrestor

in the flare line to prevent the flash back you run the risk of an explosion. The Auto

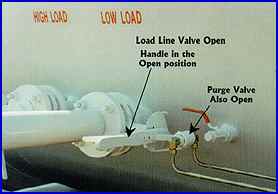

Purge Valve Assembly ensures that when the truck driver opens the load line valve to draw

fluids from the storage tanks a piggyback ball valve automatically opens to allow gas

pressure to flow into the storage tank and displace the fluid that is being removed. As

this gas pressure enters the tank and displaces the removed fluid it does not allow or

require air to be pulled into the storage tank thus eliminating corrosion and explosion

problems.

The key feature is that when the load line is opened the displacement gas is automatically

turned on for operator ease and safety.