| |

|

|

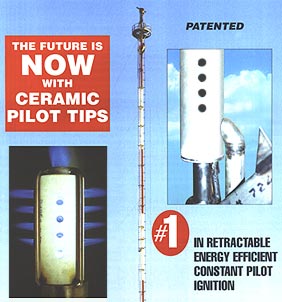

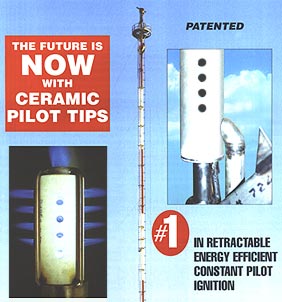

TECHNICAL

BREAKTHROUGH

FOR ADVANCED PILOT SYSTEM

Silica

Nitride has been used for high tech engine valves, high pressure pistons,

ball bearings used in the space shuttle landing gear that last 10 times

longer than the best steel bearings available, metal forming wear resistant

rollers, machine tool cutting bits and more. Now TORNADO™ TECHNOLOGIES

INC. has

incorporated this cutting edge technology into newly engineered ceramic

pilot nozzles for flare ignition pilots. This new breakthrough will insure

long lasting and more dependable ignition pilots for the petroleum industry

onshore and off. Please inquire about these state of the art non-corroding

ceramic flare pilots for your flare equipment. Don't settle for out dated

standard stainless steel pilot nozzles. When you have a critical condition

go, with the best. Go with TORNADO™ ceramic technology.

The only proven and used ceramic pilot head

with hundreds in service in the most adverse sour gas conditions in the Western Canada oil

and gas industry. Our reputation speaks for our quality. |

| Over

3000 in use today for most major petroleum and processing industry

companies - many can be found in the harshest conditions possible. |

|

|

FEATURES:

• Constant pilot for positive ignition, 24 hours a day

• Extremely fuel efficient compared to other pilot systems on the market. Consider

the quick pay-back with the TORNADO systems

• Totally retractable to allow easy future inspection and servicing of pilot or

thermocouples from ground level without cranes, unlike other weld on systems that are

fixed at the flare tip.

• Ceramic pilot nozzles minimizes nozzle break down (Listed in Options)

• Successfully tested for winds in excess of 200 MPH by University of Calgary

Department of Mechanical Engineering.

• Proven reliability in the most adverse and windy conditions. (Tested and used in

the mountain tops of Pincher Creek Pass)

• Backed by proven performance and service.

• Satisfaction Guaranteed.

MODELS:

TORNADO TECHNOLOGIES INC. offer ignition systems for FLARE STACKS, FLARE PITS, BURNER TUBES and

OFF-SHORE BOOMS. These systems may be equipped with the unique TORNADO PILOT MONITORING

and RELITE (TPMR) which will relight the pilot once every second until a steady burn is

achieved.

|

|

|

FUEL

CONSUMPTION:

TORNADO

STACK IGNITOR

TSI-3..Propane...4 litres/24 hours

TSI-6..Fuel Gas..15 scfh

TORNADO BURNER TUBE PILOT

TBTP-3...Propane....4 litres/24 hrs.

TBTP-6...Fuel Gas...15 scfh

TORNADO PIT IGNITOR

TPI-3.......Propane....4 litres/24 hrs.

TPI-6.......Fuel Gas....15 scfh

TORNADO PLUS PILOT

TPP-8......Fuel Gas....95 scfh

Tornado Plus Pilot is designed for economical weld on application to supply a large

dimension flame. Fuel consumption is approximately one-third of competitive windproof

pilots. May be used for oil batteries, gas wells, etc. (Mounting bracket included)

|

OPTIONS:

TCER - TORNADO™ Continuous Electronic Re-ignition

TM - Manual Relight

TPMR - TORNADO™ pilot monitoring and relite

TRI - TORNADO™ remote ignition

U.V. - Pilot monitoring and relite

TPM - TORNADO™ pilot monitoring

C.N. - Ceramic Nozzles for your very corrosive conditions (conditions

that quickly break down S.S. Nozzles)

|

|

|

STACK IGNITORS:

TORNADO™ FLARE STACK IGNITORS are designed with economy, reliability, and serviceability in

mind. Some of the TORNADO™ advantages are:

• An ignitor head which is retractable to ground level for easy manual ignition of

the pilot, eliminating the need for flare guns and shot tubes, and also allowing easy

access for servicing.

• A simple, rugged design which is effective, reliable and easily repaired, and is

economical to purchase, install, operate and maintain.

The following picture and a diagram

illustrate a small propane pilot generally used for rental portable flare stacks. It shows

the retractable concept and the wind shroud arrangement for your review. Other models and

options may differ from Letter #7 in design, depending on model and type.

|

|

|

1: Fuel line

2: TFS standard wind shroud

3: Protective pilot housing

4: Large diameter, weather

resistant pulley

5: Simplified tracking system

(Stands up to severe conditions)

6: Stainless steel hoisting cable

7: Total stainless steel housingNote:

All stainless steel pulleys available |

PILOT OPTIONS:

PILOT MONITORING AND RELITE:

This option consists of a Type K thermocouple housed in a thermo well which is positioned

in the pilot to monitor pilot status. If a pilot outage occurs, the thermocouple sends a

signal to a controller unit positioned by the stack or in the control room. This signal

tells the relite device, mounted on the back side of the retractable pilot, to relight the

pilot until the controller is satisfied that a stable pilot has been established. After

establishing a pilot, the system returns to a normal operating mode. Options such as alarm

contacts (wet or dry), and timed delay are available. Models are available in 12V, 12V

solar and 110V with battery backup (generally used in permanent plant locations where

flare does not burn continuously, but the pilot does).

TCER: The continuous electronic re-ignition

option consists of a high energy spark generator powered by a selection of power inputs.

This spark generator is set to send intermittent high voltage arcs every 40 seconds for 1

1/2 seconds to the ceramic pilot nozzle on the pilot tip. Inside the ceramic nozzle there

is a S.S. spark gap that the spark jumps across. This then lights the premixed pilot fuel

internally, where it is protected and clean. Using this method insures that there is no

delay in lighting the pilot if it should go out. Other manufacturers systems have to

premix a flame front generator, and fire it. If the fireball doesn't make it to the pilot,

it has to try again, taking excessive time.

U.V. FLARE STACK MONITORING: The U.V.

monitoring device, instead of having a thermocouple monitoring the pilot, has a detecting

eye that is mounted on a post at ground level, back away from the stack. The detecting eye

is pointed at the flare stack tip where the burning flare gas sends off U.V. rays. If the

flare goes out, the detecting eye sends a signal to the controller and tells the relite

device, mounted on the backside of the retractable pilot, to relight the stack. Once the

stack is relit, the detecting eye detects the U.V. rays, and the system returns to normal

standby condition. Models are available in 12V, 12V solar and 110V with battery backup

(generally used in locations where the flare is burning continuously).

REMOTE IGNITION: This remote ignition option

is to be used where continuous pilot is not required, but the flare stack is ignited

intermittently from a remote location. To operate the system, you simply turn on the fuel

to the pilot and relite device, and push the ignition button. The relite device, on the

backside of the pilot, will relight the pilot for as long as you hold in the ignition

button. Manual Remote Electronic Systems are also available. Models are available in 12V

off of truck battery, 12V solar or 110V A.C..

The above options can be used on flare pits and heating system burners as well. For

technical information, please call our office.

APPLICATIONS

TORNADO™ SYSTEMS are utilized in a wide variety of industrial applications, including heavy

oil, oil batteries, compressor stations E.S.D.S., loading terminals, off-shore booms and

other uses.

ADVANTAGES

• Ceramic Nozzle for long life.

• Wind proof.

• Constant Pilot.

• Fuel Efficient.

• Positive ignition at variable flow rates.

• Very durable in H2S conditions.

• Greater ignition area.

• Withstands the most severe heat.

• No carbon build-up.

• Ignites within a windshield.

• Can be designed to fit any stack.

• Safe in green areas.

• Simple to repair in remote areas.

• Economical.

• Simple, rugged, effective design.

• Options to suit.

• No electrical interference to local t.v.

• No flame fronts.

FLARE STACKS:

TORNADO™

FLARE STACKS are custom built, competitively priced stacks for sweet or sour

service. Free standing or guyed single, dual, triple and air assist stacks are available.

These stacks are engineered and come as complete packages.

SERVICES:

A complete range of services from start to finish are also available, including:

• Computer design and drafting of systems.

• Transportation of systems to assembly site

• Installation and testing of systems at location.

• Rental purchase plan.

Back

To Product Information