|

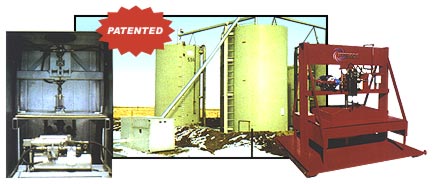

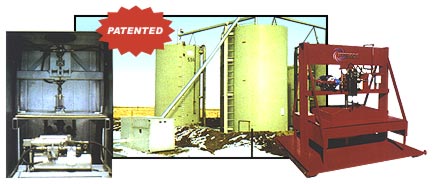

PRODUCTION TANK VAPOR TRANSFER PUMP |

"We've got

your Vapor Breakout Problem in the Bag"

The vapor transfer pump works on very low positive pressure created by breakout in the production or storage tanks. This low pressure flows into an easily expandable bladder, which expands to the rate of demand from the gas breakout in the tank or tanks. The bladder is positioned on a table platform support. On the other side of the bag is a continuously reciprocating disk. As the disk travels up and down, it discharges any gas that the bladder has accumulated. The pump does not discharge any gas unless it has entered the bladder, where it is then discharged out to the stack. The reciprocating disk is not fastened to the bladder, so it does not create any vacuum, this eliminates air from being drawn into the tank. The advantages of this system are: it is safer; no explosions: tank tops last longer because of no air intake. It is totally self-governing, at very minimal pressures, without complex controls, no metal to metal blowers to maintain, and it minimizes or eliminates purge and drive gas consumption.

|

|

|

|

|

| • | Flow to bladder starts at anything above atmospheric pressure. |

| • | Discharge pressure to flare is 5 psi. |

| • | 5 psi stall eliminates overstress on pump. |

| • | Unit sized 0 to 400,000 SCFD. |

| • | Pump comes housed in an insulated metal building that contains heat to prevent check valves, bladder and all working parts from freezing. |

| • | Custom build to suit application if required. |

| • | No complicated valving to fail. |

| • | COMPARE this system to others. We will show you the advantages of these systems and why the Tornado Vapor Transfer Pump is SAFER and MORE RELIABLE. |